Products

Safety Cabinets

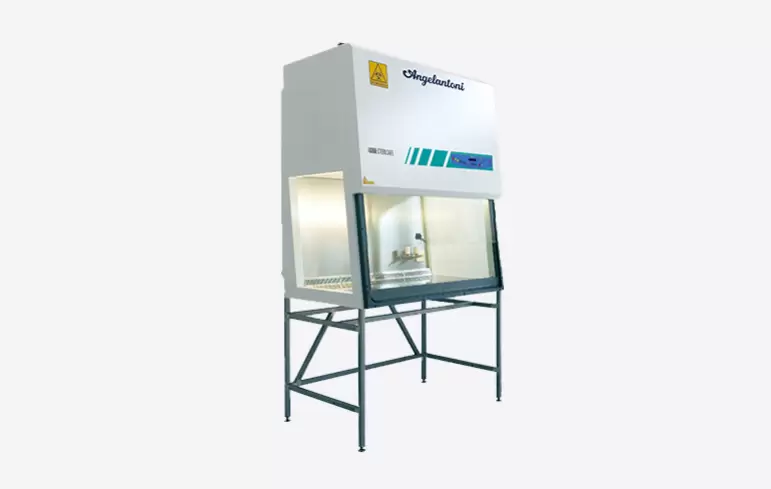

Sterlisafe

He series of Class II microbiological safety extractor hoods are designed and manufactured according to the performance requirements of EN12469: 2000 and are used in all situations where it is necessary to protect the operator and the environment from the harmful effects of uncontrolled spreading of airborne contaminants and, equally, to ensure that no environmental interference of a microbiological nature can affect the product during its handling.

Class II they are equipped with a partial frontal working opening allowing the suction of 30% of the total air involved at a minimum speed of 0.4 m/s and a recirculation system for the remaining 70% which is sent to the working area in laminar flow at an average speed of 0.4 m/s (as defined by EN 12469 standards).

Type A1, according to NSF 49 (U.S.A.) standards, can be used safely even if the expelled air coming from the frontal barrier is returned to the environment.

Type A2 as, according to NSF 49 (U.S.A.) regulations, the expelled air can be channeled towards the outside of the room where it is used (for further technical details see the dedicated paragraph).

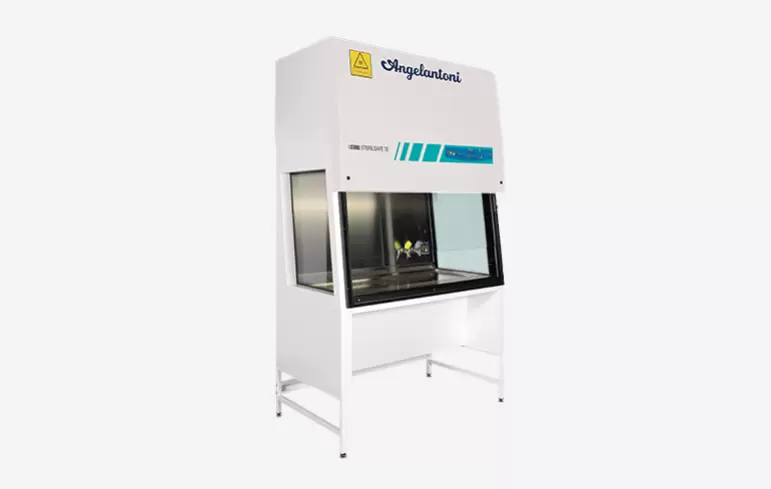

Sterilsafe TE

The series of Class II microbiological safety extractor hoods are designed and manufactured according to the performance requirements of EN12469: 2000 and are used in all situations where it is necessary to protect the operator and the environment from the harmful effects of uncontrolled spreading of airborne contaminants and, equally, to ensure that no environmental interference of a microbiological nature can affect the product during its handling. These hood lines areBIOHAZARD . Type B2 as they discharge all the air involved. They are designed to provide protection for the operator, the product and the environment and to expel 100% of the air outside the building.

Bioban

The series of Class II microbiological safety hoods, designed and built according to the performance requirements of EN12469: 2000, is used in all situations where it is necessary to protect the operator and the environment from the harmful effects of uncontrolled spreading of airborne contaminants and, equally, to ensure that no environmental interference of a microbiological nature can affect the product during its handling.These hood product series are classified as BIOHAZARD. Class II as they are equipped with a partial frontal working opening allowing the suction of 30% of the total air involved at a minimum speed of 0.4 m/s and a recirculation system for the remaining 70% which is sent to the working area in laminar flow at an average speed of 0.4 m/s (as defined by EN 12469 standards).

Type A1, according to NSF 49 (U.S.A.) standards, as can be used safely even if the expelled air coming from the frontal barrier is returned to the environment.

Type A2 as, according to NSF 49 (U.S.A.) regulations, the expelled air can be channeled towards the outside of the room where it is used (for further technical details see the dedicated paragraph).

Gemini

The GEMINI extractor hood, available in one size, is normally used in microbiology and molecular biology laboratories and increasingly so in a wide range of other applications:

• Quality control in the food industry ,

• Micromechanical assemblies ,

• Nucleic acid amplification and thermocycling.

Positive pressure vertical laminar flow hood, compact (800 mm) with partial recirculation - designed for protection of the product.

Cth EVO

The hoods in the CTH EVO line are used in all situations where it is necessary to protect the operator and the environment from the harmful effects of uncontrolled spreading of airborne contaminants and, equally, to ensure that no environmental interference of a microbiological nature can affect the product during its handling.Protection of the product: Cleanliness of the air in the working area in Class ISO 3 as per ISO EN 14644-1

Protection of the environment: This involves filtration of the expelled air quota with EN 1822 compliant HEPA H14 filters with an efficiency of 99.995% MPPS (equivalent to 99.999% on 0.3m particles with DOP/DOS test) .

Cytobox

CYTOBOX cytotoxic isolators are negative pressure glove boxes with 2 transfer pass boxes. They are used to separate a pharmaceutical process or activity from both the operator and the surrounding environment in the case of reconstituting freeze-dried drugs and handling toxic materials. Designed for the safe preparation and handling of hazardous substances such as cytotoxic drugs and safe handling of antineoplastic chemotherapy drugs and CMR substances.Fresh air is sucked from the top of the pass boxes through an H14 HEPA / ULPA filter and pushed into the working area of the pass boxes. Then air passing through a second HEPA / ULPA H14 filter is drawn in by the main fan.

The pressurized air pushed into the plenum passes through the HEPA / ULPA LAF H14 filter and then downwards, in a laminar flow, into the work chamber to protect the products being handled. From here, the air is sucked into the main HEPA / ULPA H14 filter underneath the working surface, and then the air passes through the channel at the rear of the working chamber.

Part of the air is expelled through the exhaust HEPA H14 filter; this process creates a negative pressure condition in the working area to protect the operator and the environment.

Cytobox Light

CYTOBOX LIGHT cytotoxic isolators are negative pressure glove boxes with pass boxes integrated into the work surface. They are used to separate a pharmaceutical process or activity from both the operator and the surrounding environment in the case of reconstituting freeze-dried drugs and handling toxic materials. Designed for the safe preparation and handling of hazardous substances such as cytotoxic drugs and safe handling of antineoplastic chemotherapy drugs and CMR substances.CYTOBOX LIGHT can be used in various ways in hospital oncology centers for the preparation of drugs and whenever a high and proven degree of protection for operators is required. In particular, the isolator is suitable for the following applications:

preparation of antineoplastic chemotherapy drugs,

handling of cytotoxic and cytostatic drugs,

handling of aetiological agents of proven and active pathogenicity in humans and animals,

handling of highly concentrated pathogenic compounds and mutagenic agents,

oncogenic viruses,

microbiology, virology and cell culture

applications of recombinant DNA.

Cth

The hoods in the CTH line are used in all situations where it is necessary to protect the operator and the environment from the harmful effects of uncontrolled spreading of airborne contaminants and, equally, to ensure that no environmental interference of a microbiological nature can affect the product during its handling.Protection of the operator: The containment index, evaluated over the total surface area of the frontal suction area, is equal to or less than 5 CFU for a non-turbulence test or APF equal to or greater than 1x105 according to EN12469.

Protection of the product: Cleanliness of the air in the working area in Class ISO 3 as per ISO EN 14644-1

Protection of the environment: This involves filtration of the expelled air quota with EN 1822 compliant HEPA H14 filters with an efficiency of 99.995% MPPS (equivalent to 99.999% on 0.3m particles with DOP/DOS test)

POLARIS

POLARIS extractor hoods are used in microbiology, virology and hematology laboratories. They are increasingly used in research and in particular for the sterile handling of:

•Non-pathogenic cell cultures ,

•Quality control in the pharmaceutical and food industry ,

•Micromechanical assemblies ,

•In vitro fertilization .

Helios

The Helios range of hoods is Horizontal laminar flow hoods. They are used in all situations where the product needs to be protected from harmful effects due to the uncontrolled spread of airborne contaminants during handling.They are normally used in microbiology laboratories. , They are increasingly used in various fields of research and in particular for the sterile handling of:

•Quality control in the food industry ,

•Micromechanical assemblies ,

Top Flow 2

TOP FLOW 2 is a BIOHAZARD DUAL FRONT class II vertical laminar airflow cabinet for changing animal cages, designed and built according to the performance requirements of EN12469: 2000. They are normally used in pharmaceutical testing and research laboratories. Epoxy powder coated housing, work surface made of TRESPA material, dimmable LED lights and side safety glass.

Hinged front windows, microprocessor monitoring system, full status report via 2-line digital display, audio-visual alarms, intuitive keypad and digital display.